Quality Check Performed at Our Factory

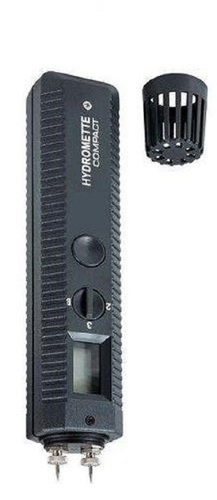

At our factory, quality check is performed at every stage of the production process to ensure that the final product meets the highest standards of quality and performance. From the raw materials to the finished product, each stage is thoroughly inspected and tested to ensure that it meets our strict quality standards. Our team of skilled professionals uses advanced quality control tools and techniques to perform these checks, and all of our machines are regularly maintained to ensure that they are operating at their best. Our commitment to quality is unwavering, and we are proud to deliver products that are reliable, durable, and of the highest quality.